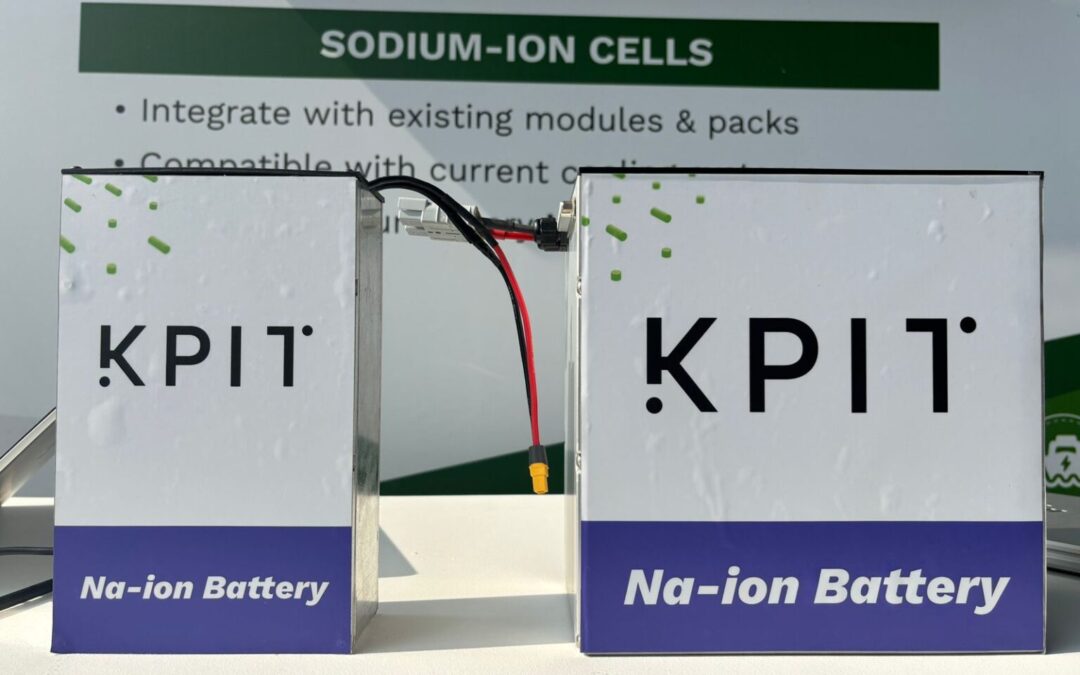

Pune-based KPIT Technologies an independent software integration company, instigated its sodium-ion battery technology, focusing on reducing import dependency on critical battery materials.

The sodium-ion battery technology for e-mobility applications in India unveiled by KPIT technologies is especially for electric 2 & 3-wheelers and commercial vehicles, along with other stationery deployments including UPS backups and grid storage.

Co-founder and Chairman of KPIT Mr. Ravi Pandit said “ This sodium-ion battery technology is prophesied to lower the cost of electric vehicle batteries by an estimated 25-30% compared to existing lithium-ion batteries.

Currently, lithium-ion cells are subjugating the global shift to electric vehicles encouraging countries like India to localize the supply chain to lessen the risk associated with geopolitical tensions.

At present India is importing 70% of its lithium-ion cells from its contiguous countries.

By 2030 Indian lithium-ion battery market is expected to grow from 4GWh in 2022 to 120 GWh by 2030, with a 53% compound annual growth rate in demand.

The sodium-ion battery technology introduced by KPIT aims to address import dependency challenges on core battery materials.

KPIT claims sodium-ion batteries compared to lithium-ion batteries serve several advantages, including a prolonged lifespan with 80% capacity retention over 3000-6000 cycles and speedy charging capabilities.

KPIT Is Open To Collaborate For Battery Production

KPIT is open to collaborating with battery manufacturers for the production of these batteries using its proprietary sodium-ion technology in an effort to contribute to a sustainable mobility ecosystem.

The move towards sodium-ion batteries is seen as strategic heterogeneity from the ascendancy of lithium-ion batteries conveying concerns about the concentration of lithium supplies in a few countries.

Key Highlights of this Sodium-Ion Battery Technology

- Majorly reduce the cost of ownership and increase the vehicle uptime, thereby increasing income.

- Fast charging than common lithium batteries.

- Several alternatives have distinct performance characteristics and energy densities ranging from 100-170 Wh/Kg.

- Excellent high-temperature forbearance with minimal thermal management.

- Augment Safety.

India aims to overcome challenges such as import dependence on key battery raw materials, high Electric Vehicle battery costs, and the absence of domestically manufactured cell technology as the country is targeting to electrify 30% of its vehicle fleet by 2030.

Image Source: pv-magazine-India